Streamlining Biopharmaceutical Manufacturing Processes with Single-Use Assemblies

Tri-Canada offers an extensive catalog of quality sanitary process solutions developed to meet the exact needs of the Pharmaceutical and Biotech, Food Beverage and Brewing, and Cosmetics industries.

Preventing cross-batch and cross-product contamination and ensuring hygienic manufacturing conditions is essential to the success of pharmaceutical, cosmetics, food processing and beverage manufacturing companies. Tri-Canada provides fully traceable records upon request, enabling industrial processing manufacturers to meet strict regulatory requirements of the USDA, FDA and other governmental agencies.

Connect with a Tri-Canada team member to discuss your single-use needs!

Out Products Include:

& many more!

FEATURED

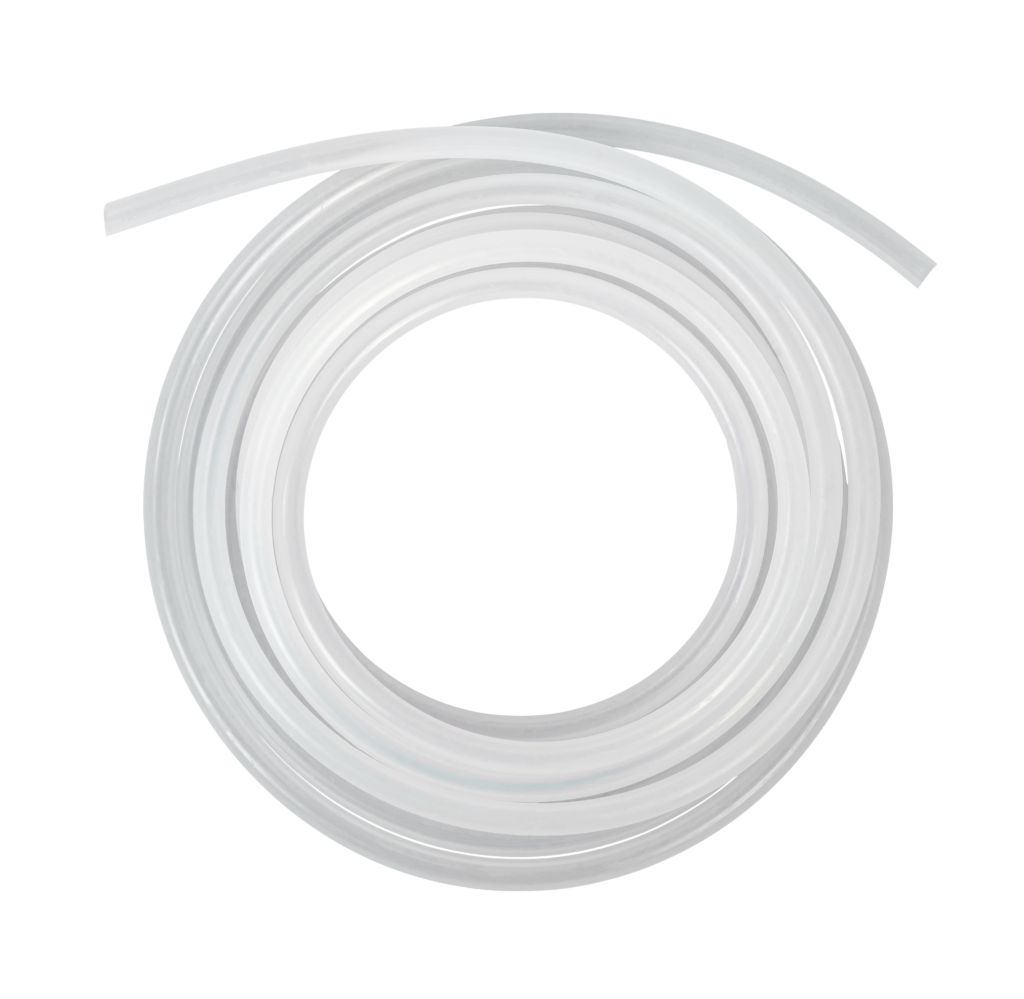

Biopharmaceutical Grade Silicone Tubing

Purity One™ OneSil biopharmaceutical grade silicone tubing has been formulated for demanding and critical fluid transfer applications in biopharmaceutical processing.

The Ideal Choice for:

- Sterile Filling and Transfer

- Sampling

- Pumping

- Single-Use Assemblies

- Filtration

- Buffer + Media Prep + Processing

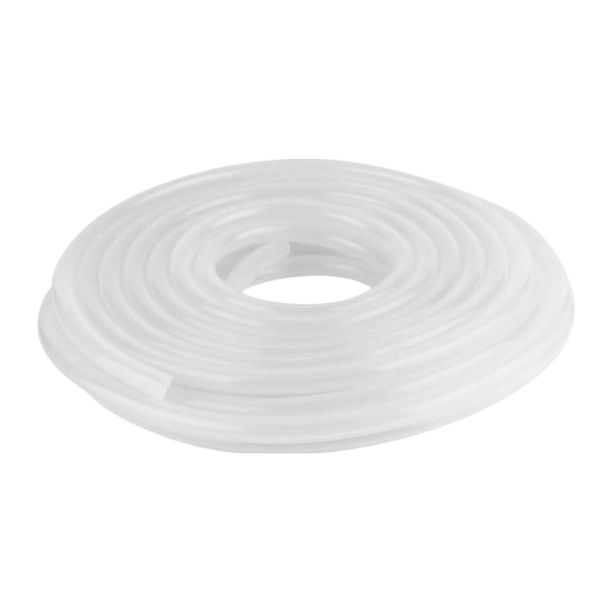

Biopharmaceutical Grade TPE Tubing

Biopharmaceutical grade TPE tubing has been formulated for demanding and critical fluid transfer applications in Biopharmaceutical processing. OneFlex is an excellent choice for applications that require heat sealing and sterile welding capabilities.

The Ideal Choice for:

- Aseptic Welding Connections

- Aseptic Sealing Disconnections

- Filtration

- Sterile Filling and Transfer

- Sampling

- Single-Use Assemblies

Our Trusted Partners

WE ARE COMMITTED TO PROVIDING QUALITY SOLUTIONS

Tri-Canada is a proud supplier of the top product lines for biotech, pharmaceutical and food & beverage industries. We partner with the best companies to bring you an unmatched array of components to meet even the toughest application requirements. From tubing to single-use assemblies to pumping solutions, Tri-Canada has the selection you need with expert guidance to match, ensuring you get the right product for your application every time.