Industry Leading Pump Solutions

Sanitary pumps are specifically designed for use in industries such as food, pharmaceuticals, and personal care, where it is important to maintain clean and hygienic conditions. These pumps are constructed using materials that are resistant to corrosion, such as stainless steel, and they are engineered to adhere to strict industry standards for hygienic performance.

The primary purpose of sanitary pumps is to facilitate the movement of liquids and semi-solids within a system, such as transferring products from one stage of processing to another. There are various types of sanitary pumps available, each with its own set of advantages and disadvantages. It is crucial to select the appropriate type of sanitary pump for a particular application and to ensure proper maintenance and optimization of its performance. This is essential in order to uphold hygienic conditions, ensure product quality, and prioritize safety.

Connect with a Tri-Canada team member to discuss your sanitary pump needs!

Our Products Include:

& many more!

FEATURED PRODUCT

OnePump VersaFlow

FEATURED PRODUCT

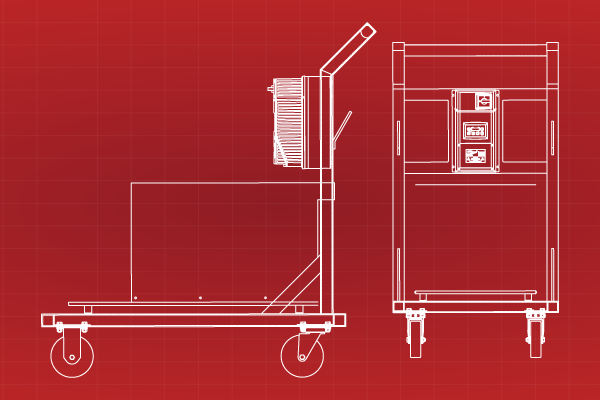

Pump Cart Solutions

Custom Pump Cart Solutions incorporating Quattroflow, Watson-Marlow, Masteflex and other pump brands

AVAILABLE OPTIONS:

- 1/2-5 HP frame mounted motors

- Sperate VFD controls

- Integrated flow, pressure and weight

- Shelf locations: Top, bottom, or no shelf

- Wheels: Swivel, fixed, non-marking

- Tubing / hose management

- Power cord wrap

- Custom cart dimensions

Optimizing Your Sanitary Pumps

Maintaining hygienic conditions and ensuring product quality and safety heavily rely on the optimization of sanitary pump performance.

To achieve this, it is crucial to prioritize regular maintenance activities. This involves conducting inspections to identify and replace any worn or damaged parts, as well as lubricating moving components and checking for leaks or other potential issues.

Additionally, proper cleaning practices play a vital role in upholding sanitary conditions and preventing contamination. Although sanitary pumps are designed for easy cleaning, it is important to adhere to appropriate cleaning procedures and use suitable cleaning agents. This will prevent any damage to the pump and avoid leaving behind residues that could contaminate the product.

Monitoring the performance of the pump is also essential in order to proactively address any emerging problems. This includes being attentive to unusual sounds or vibrations, monitoring flow rates and pressures, and conducting regular inspections of seals and other integral components.

By following these optimization strategies, you can ensure that your sanitary pump operates at its utmost potential, delivering the highest standards of product quality and safety.

Our Trusted Partners:

WE ARE COMMITTED TO PROVIDING QUALITY SOLUTIONS

Tri-Canada is a proud supplier of the top product lines for biotech, pharmaceutical and food & beverage industries. We partner with the best companies to bring you an unmatched array of components to meet even the toughest application requirements. From tubing to single-use assemblies to pumping solutions, Tri-Canada has the selection you need with expert guidance to match, ensuring you get the right product for your application every time.