T-FIT Insulation Offers a Trustworthy Insulation Solution for a Variety of Manufacturing and Cleanroom Environments

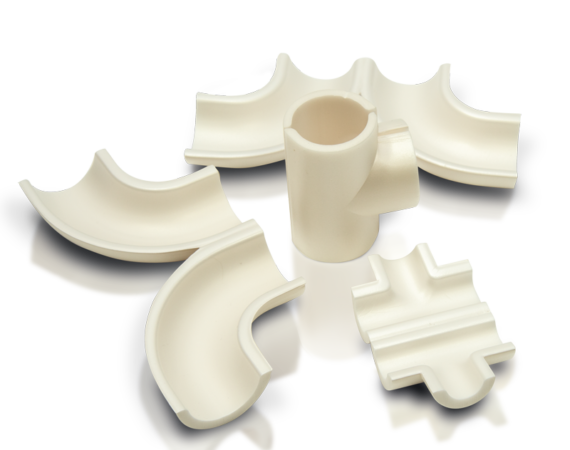

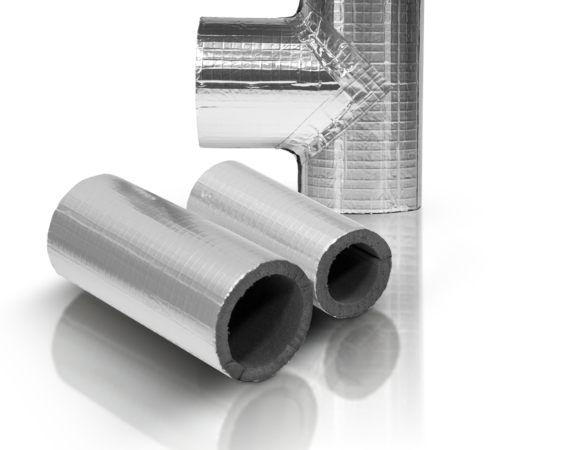

T-FIT Insulation offers products for a variety of manufacturing and cleanroom environments. With unmatched performance and minimal maintenance, T-FIT offers a trustworthy solution for your application. From start to finish, T-FIT makes insulation decisions easy. Installation is simple and straightforward, even when time and space are tight. The modular design of the insulating components makes maintenance inspections a simple ‘open and close’ operation. And with a decade and more of active service ahead, the investment is easy to justify. Not only does the T-FIT range combine the highest performance with the highest levels of protection from an insulation material, but a service life measured in years makes for a Total Cost of Ownership that boosts the bottom line.

Connect with a Tri-Canada team member to discuss your piping insulation needs!

Our Products Include:

& many more!

When and Where to Use Piping Insulation

Piping insulation is essential in sanitary manufacturing settings to prevent contamination, maintain a sterile environment, and ensure product quality and safety. Here are some examples of when and where piping insulation is commonly used in sanitary manufacturing:

Food and beverage processing: Insulation is used to maintain precise temperature control in food and beverage processing facilities to prevent spoilage and ensure product quality. Insulated pipes also prevent condensation from forming on the surface of the pipes, which can lead to contamination.

Pharmaceutical manufacturing: Insulation is used in pharmaceutical manufacturing to prevent cross-contamination and maintain a sterile environment. Insulated pipes also help to maintain precise temperature control, which is essential for pharmaceutical processes.

Biotech manufacturing: Insulation is used in biotech manufacturing to maintain a sterile environment and prevent contamination. Insulated pipes also help to maintain precise temperature control, which is important for biotech processes.

Dairy processing: Insulation is used in dairy processing facilities to prevent spoilage and ensure product quality. Insulated pipes also help to maintain precise temperature control and prevent condensation.

In sanitary manufacturing settings, the specific type and thickness of insulation used must meet industry standards and regulations for cleanliness and safety. Insulation materials must be non-toxic, non-absorbent, and easy to clean to prevent contamination. In addition, installation of the insulation must be performed using sanitary techniques to prevent contamination during installation.

Our Trusted Partners

WE ARE COMMITTED TO PROVIDING QUALITY SOLUTIONS

Tri-Canada is a proud supplier of the top product lines for biotech, pharmaceutical and food & beverage industries. We partner with the best companies to bring you an unmatched array of components to meet even the toughest application requirements. From tubing to single-use assemblies to pumping solutions, Tri-Canada has the selection you need with expert guidance to match, ensuring you get the right product for your application every time.